Copy of Article Text Below

.....the special Fordair fleet of aircraft running a scheduled service between Stanstead and the Cologne-Bonn airport are booked solid for every flight, and in fact many of the top engineers divide their time each week between the two Engineering Centres.

Of the two, Dunton was the first to be completed, being opened by the then Prime Minister in October, 1967. jt covers 15 acres of a 268 acre site and employs 3,300 people. Among its facilities are a small proving ground and a styling studio. Before it was built, Ford engineering development was scattered in nine or so different places including Aveley, though advanced engineering was concentrated in Lodge Road, Birmingham, where a new research centre was built in 1955 on the site of an old glass factory. Here among other developments a two cylinder engine was designed and tested. This followed the introduction of the Mini in 1959, when Ford gave o very serious consideration to building a small car.

After buying a Mini, stripping it right down and carrying out an intensive cost analysis of all its components at the Birmingham Engineering Centre, Ford came to the conclusion it was not making any money for BMC, as it was very expensive to manufacture. In fact, I can remember John Barber who was then Ford Director of Finance coming to lunch with the staff of Motor and astounding us with the prophetic statement that the Mini would bankrupt BMC. For of course we had all been greatly impressed by the car.

It was the fact that the smaller the car, the more difficult it was to make at a profit that has in the past put paid to so many previous Ford small car projects. The formation of Ford of Europe made it possible to build a small car in much greater numbers than had hitherto been thought possible and it made the Fiesta project practical financially.

The first mock-up was built in 1970 in the Merkenich styling studio and although a great deal of development subsequently took place, the basic concept of the type of small car Ford were to build changed remarkably little. The outward shape of the car changed considerably, of course, with designs and mock-ups coming not only from the styling studios at Merkenich and Dunton, but also from Ghia which Ford had bought and merged with their existing styling studio in Turin, and from Gene Bordinat's stylists in Dearborn. The entire project, in fact, was transferred across the Atlantic to the Dearborn Engineering Centre in 1971-72 to enable the Ford of Europe Engineering Centres to concentrate on the replacement Escort.

Our colour centre spread show just some of the prototypes and mock-ups which were considered, many of which contributed ideas to the production version. It is interesting that the three door configuration was not finally adopted until fairly late in the programme, and even then there were thoughts on retaining a two door version for the less expensive models in the range. The three door body has much to commend it, but it is more expensive to build. The general body structure has to be strengthened to make up for the bigger aperture at the rear, the rear seat has to be made to fold, as must the parcel shelf, and substantial struts have to be provided for the rear door. Moreover, the cargo space at the rear has to be capable of taking much more punishment than a normal boot, because people load a three door car with objects they would never think of putting in the boot.

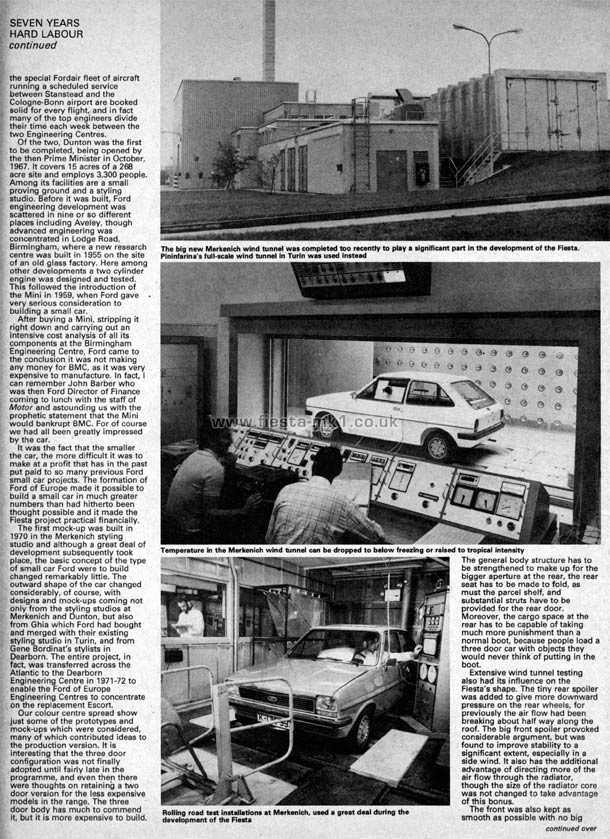

Extensive wind tunnel testing also had its influence on the Fiesta's shape. The tiny rear spoiler was added to give more downward pressure on the rear wheels, for previously the air flow had been breaking about half way along the roof. The big front spoiler provoked considerable argument, but was found to improve stability to a significant extent, especially in a side wind. It also has the additional advantage of directing more of the air flow through the radiator, though the size of the radiator core was not changed to take advantage of this bonus. The front was also kept as smooth as possible with no big.....

Captions -

Top-Right - The big new Merkenich wind tunnel was completed too recently to play a significant part in the development of the Fiesta. Pininfarina's full-scale wind tunnel in Turin was used instead

Middle-Right - Temperature in the Merkenich wind tunnel can be dropped to below freezing or raised to tropical intensity

Bottom - Rolling road test installations at Merkenich, used a great deal during the development of the Fiesta

|